|

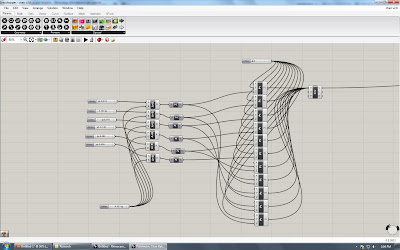

| Screenshot: Entire Script |

Our next attempt utilizes a simple Cos(X) function to generate the cross section of the seat. Using the cosine function allows us to adjust the contour of the seat more rapidly than before, where we had to adjust each control point with an individual slider. With the cosine function we are able to adjust multiple points along a curve at once.

|

| Screenshot: Start, Divides seat section into 8 nodes, places a frame and provides start point for each section curve |

When the cosine equations are created they automatically want to start at the origin in Rhino. To relocate them to a specific start point we created a spline that represented our desired seat cross section in profile. We then divided that spline into seven parts and placed a frame at these divisions. extracting the x,y,z value at these intersections we were able to assign this as the origin for each equation, giving us an adjustable cosine curve at seven locations along the section of our chair.

|

| Screenshot: Middle, Cosine equation Parameters, allows editing of curvature |

By editing the Amplitude, period and frequency of the COSX function, we are able to generate different seat depths and widths. Seven of these functions are employed across the entire seat. Variation to each equation changes the character of the chair from seat back to seat.

| |

| Screenshot: End, lofts curves and mirrors them to make the complete chair. | | | |

|

To generate a surface from this data we then take the curves generated from the Cos(x) function and loft them. Because these curves only represent half of the chair we then mirror this surface to create a complete and symmetrical seat.

|

| Screenshot: Seat with Seatback derived from 7 sections |

This is what the seat looks like based on the script we have written. Not bad. You can already begin to see the making for a seat and a seat back.

We then begin to tweak the sliders associated with the cosine function and you can see how we are able to drive formal responses. We will now be able to use rhino to help out put our first prototype.

|

| Screenshot: Editing Varibles for seat section Equation |